Aerospace and Defense

High-Reliability Sensors and Shunts for Air, Land, Sea and Space

Air

Any air vehicle with an electrical system is a potential application for our high-reliability voltage and current sensors. This includes lighter-than-air, heavier-than-air, crewed or remotely-piloted.

Land

Land-based systems (vehicles and other fixed and mobile equipment) can improve performance efficiency and reliability by including voltage and current sensors to monitor the health of on-board electrical systems.

Sea

The many complex systems on-board marine platforms (both surface and sub-surface) need high-reliability controls and performance monitoring that can easily be added with voltage and current sensors.

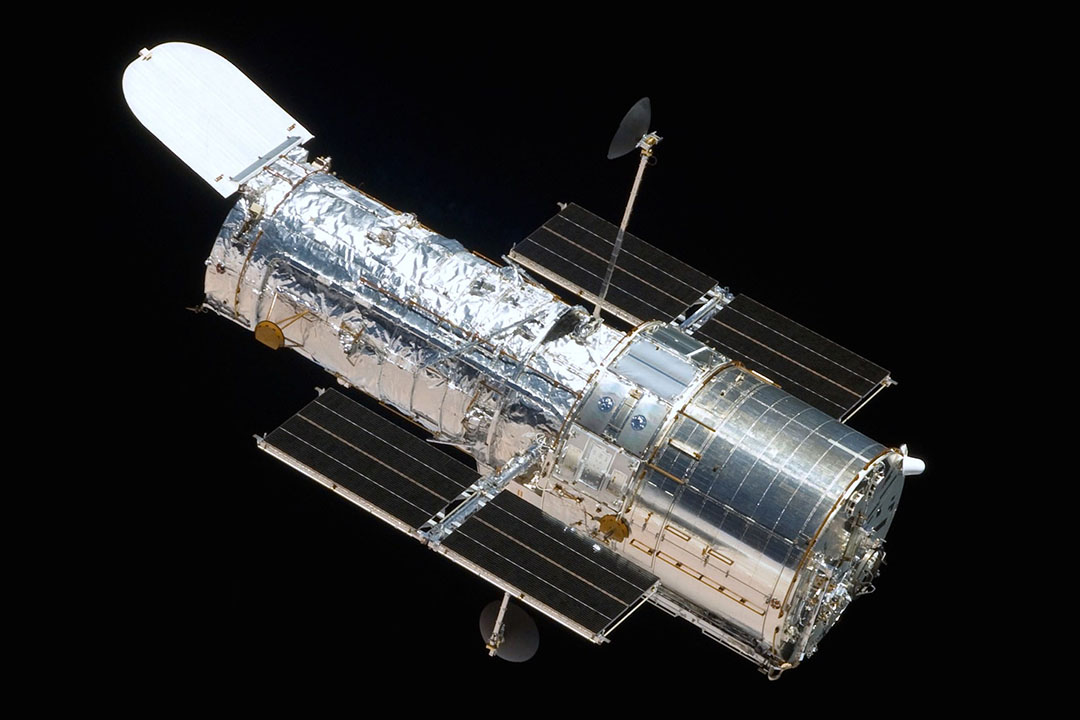

Space

Voltage and current sensors on spacecraft, both launch and deep space vehicles, provide additional visibility and security into the operational health and performance.

Air

AAC current and voltage sensors and shunts have been used on numerous aircraft and Unmanned Aerial Vehicle (UAV) programs since the mid-1960s. AAC has extensive knowledge and decades of experience in designing and manufacturing sensors, transducers, detectors and shunts. These sensors and shunts are capable of providing high reliability in harsh remote environments. For over fifty years AAC has been the market leader in quality and innovation.

AAC engineers worked extensively with Boeing/Vertol to design and develop custom sensors for most variants of the CH-47 Chinook. Sikorsky also called upon AAC to create components for the Black Hawk family of helicopters. Subsequently, AAC worked with Northup-Grumman to develop sensors for the MQ-8 Fire Scout and the RQ-4 Global Hawk UAV programs.

AAC is trusted by all the major aerospace and defense manufacturers and integrators including NASA, Lockheed-Martin, Honeywell, Northrop-Grumman and Boeing. In fact, we have been awarded the Boeing Supplier Performance Excellence Award in each of the past 12 years.

AAC Current and Voltage Sensors are used by aircraft manufacturers to measure power consumption in various elements of the aircraft. Such diverse applications as indicating if power is being supplied to pitot tubes and windshield defrosting/de-icing mechanisms to measuring the current used by transport aircraft galley heating elements and much more.

Land

The M2 Bradley Infantry Fighting Vehicle (IFV) and Stryker IFV/Armored Personnel Carrier both rely on AAC voltage and current sensors to monitor and manage the power distribution systems. Their high-reliability and ability to withstand harsh environments provides for a dependable platform for troops on the modern battlefield.

The Patriot missile launcher uses AAC current sensors to monitor power distribution and consumption helping to ensure that this important battlefield defensive system operates at maximum effectiveness.

Sea

Modern aircraft carriers rely on nuclear power to remain on-station for extended periods. These nuclear power plants rely on AAC current sensors which are part of the reactor control system.

The nuclear submarine fleet relies on its ability to stay submerged for extended periods. This requires an advanced life support system that needs to be dependable. AAC current sensors form a vital part of these life support systems which, in turn, support the advanced capabilities of these invaluable assets.

Space

Spacecraft systems operate in the harshest of conditions. Extremes of temperature, both hot an cold, vibration (during launch) and pressure stress systems and components. The lack of gravity is an additional challenge when designing the cooling systems. Further, if a part fails, it cannot be repaired of replaced. Many space systems designers rely on AAC voltage and current sensors to provide health monitoring as well as sysms controls.

AAC supplied 34 sensors for the Hubble Space Telescope and, more than 32 years later, all are operating nominally.

AAC current sensors from a part of the Thrust Vectoring Control System (TVCS) on the Arianespace Vega launch vehicle. The TVCS controls and maintains the vehicle’s attitude during powered flight ensuring that the payload is delivered to the correct orbital slot.

AAC is trusted by all the major aerospace and defense manufacturers and integrators including NASA, Lockheed-Martin, Honeywell, Northrop-Grumman and Boeing. In fact, we have been awarded the Boeing Supplier Performance Excellence Award every year since 2010.

AAC Current and Voltage Sensors are used by aircraft manufacturers to measure power consumption in various elements of the aircraft. Such diverse applications as indicating if power is being supplied to pitot tubes and windshield defrosting/de-icing systems to measuring the current used by transport aircraft galley heating elements and much more.

AS9100/ISO 9001 Certified

The essence of AS9100/ISO 9001 is embodied in the AAC culture with the focus for continuous improvement. This culture not only sustains reliability but uses new technologies to meet new environmental challenges posed by military standards as well as DO-160 commercial standards. The engineering and manufacturing capabilities are constantly being reviewed and updated where necessary to meet customer performance and reliability needs.

American Aerospace Controls’ current and voltage sensors can be found on spacecraft, rotorcraft and fixed wing platforms in the defense and commercial markets. These platforms are used worldwide and placed into service in harsh remote environmental conditions where serviceability is not a practical option. This is where reliability can not be mitigated and AAC steps forward with the capability to successfully meet these challenges.